Brood-Grow Manure Belt Cages for Eggs

Modular Manure Belt Pullet Cages

Chore-Time’s Modular Manure Belt Cage System offers egg producers the outstanding pullet performance they expect from Chore-Time, plus greater shipping simplicity, and easier assembly and repair – all in an economical cage system that meets current bird space standards. Layer systems are also available.

Chore-Time cages are quality built in North America. Solid construction and heavy-duty materials combine with our innovative design for years of superior performance.

Galfan® floors provide years of trouble-free use. Individual floors allow for easy manure belt access.*

*Galfan is not owned or licensed by CTB, Inc. and is the sole property of its respective owner.

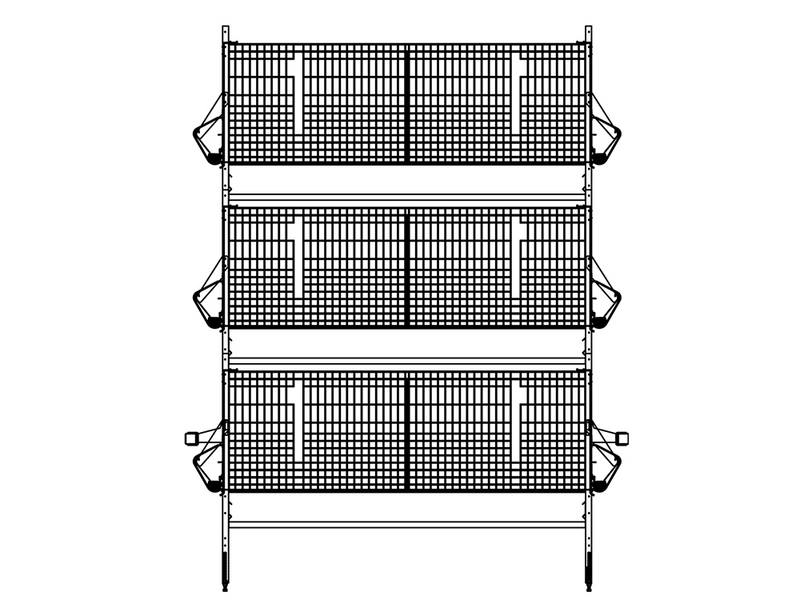

- Cages are available in 3-high to 8-high models in cage rows up to 520 feet (160 meters) long; walkways and/or step rails are easily integrated.

- Modular design features individual cages instead of eight-foot (2.4-meter) cage sections – makes cage replacement and manure belt access easier.

- Easy assembly features innovative interlocking parts, and requires fewer rings

- Brood-Grow cages feature a large push-in door for wide access to the cage interior. The door closes with a simple, yet secure spring mechanism.

- For even greater durability, cages and structural components are manufactured using all galvanized steel construction and Galfan® cage floors.

- Mesh partitions improve ventilation.

- The feed shield can be remotely adjusted (optional feature) for easy adjustment and continued feed conservation while birds grow.

- Floor support is simple solid rod construction. Does not require constant end-row tension.

- System is covered by Chore-Time’s generous cage warranty and solid backing. (See Chore-Time’s full written warranty for complete warranty details.)

*Galfan is not owned or licensed by CTB, Inc. and is the sole property of its respective owner.

- Each tier has a separate drive unit with its own motor and can be operated independently of the others as needed.

- Modular construction makes Chore-Time’s system easier to install. Plus, parts are interchangeable between tiers.

- Rubber-coated drive roller is coupled with steel pressure rollers – a combination that allows reliable belt operation on cage row lengths up to 520 feet (160 meters).

- Pressure roller scrapers keep rollers clean for better tracking and improved pull of the manure belt.

- Plastic belt scraper cleans belt without cutting or damaging it. Each tier’s belt can be cleaned easily and individually.

- Uses the same proven Chore-Time gearheads and motors used in Chore-Time feeders and egg collectors.

- Drive mechanism is designed to protect critical parts from damage should a problem occur.

- Optional supplemental air tube.

- Helps reduce ammonia emissions.

- Air in tube is low in dust content and flows freely through air holes.

- Modular components offer design and output flexibility.

- Fully automatic system handles air capacities from 4,700 to 8,800 CFM (8,000 to 15,000 cubic meters per hour).

- Made of the highest quality materials for long life.